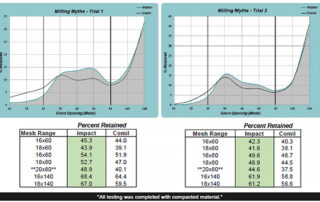

Impact Milling Vs. Comil

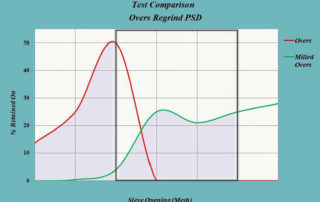

PRINT THIS POST Common Misconceptions An Impact mill creates more fines than the Comil. TRUTH: Impacting the particle reduced overall fines, as compared to the Comil “crushing” method. An Impact mill creates a wider particle size distribution compared to a Comil. TRUTH: An impact mill hits each particle with the same impact force, creating a