- HFS Hopper

- HFS

- VFS

- Hydraulic Cylinder

- Roll Gear Box

- Air Controls

- Hydraulic Cabinet

- Full Inline Sample Port

IPA takes pride in designing and manufacturing the highest quality roller compaction systems in the industry.

IPA Roller Compactors are turnkey and suited for industrial, nutraceutical, and pharmaceutical dry granulation applications. This compactor features a desired twin feed screw design, similar to the Fitzpatrick Chilsonator, with capability to independently adjust feed rate & deaeration. Specifically, the HFS controls system throughput while the VFS controls pre-compression of the material into the rolls. The twin feed screw design maintains lower system operating temperatures and is ideal for processing a wide range of materials. Additionally, it is proven to be exceptionally efficient with lighter bulk density powders containing large amounts of air.

The IPA Roll Compaction System is fully equipped with roller compactor, mill, screener, and elevator/conveyor. Our custom designed PLC control system can integrate with your up and down stream equipment and has the ability to communicate with your local DCS. Unit sizes are available for rates as low as 100 kgs/hr to 5000 kgs/hr based on product density and product yield.

Our mission is to provide more than just a high-quality machine. IPA differs from other manufacturers as we prefer to work directly with your engineers in order to customize all system components and meet your specific application requirements. Our knowledgeable team provides ongoing collaboration and aftermarket support to ensure the roll compaction system consistently runs at optimum performance.

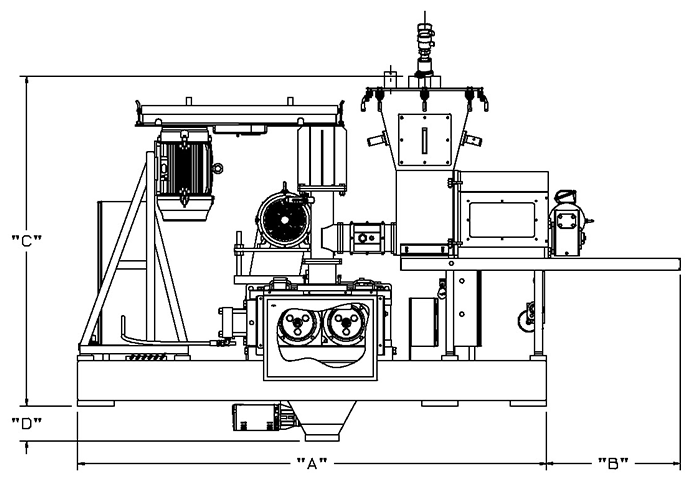

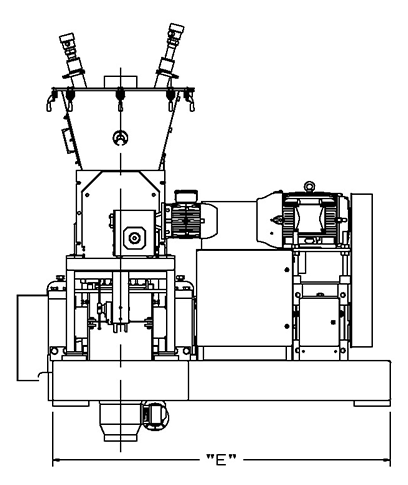

Overall Dimensions (Inches) |

||||||

|---|---|---|---|---|---|---|

| Machine Size | “A” | “B” | “C” | “D” | “E” | Weight (lbs) |

| 4×10 | 82 | 24 | 59 | 5-1/2 | 70 | 6,200 |

| 7×10 | 90 | 24-3/4 | 62-1/4 | 10-1/2 | 71 | 6,900 |

| 8×12 | 111-1/2 | 28-1/4 | 79-3/16 | 9-1/8 | 77 | 9,600 |

| 12×12 | 116-1/2 | 33-1/4 | 81-7/8 | 8-3/4 | 84 | 20,000 |

| 12×16 | 117 | 32-1/4 | 98-1/4 | 13 | 88 | 18,700 |

| 12×20 | 126 | 27-3/4 | 100 | 14 | 105 | 24,000 |

| 16×20 | 133 | 41 | 108-1/2 | 12-3/4 | 104 | 25,600 |