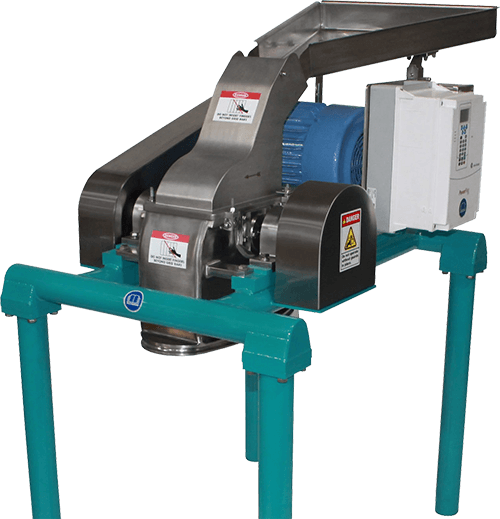

The IPA Mill

The IPA Mill is built for companies who want robust performance & durability, but with a modern and economical design. This mill provides consistent, repeatable results similar to the Fitzpatrick Fitzmill.

Mills within the industry have used the same manufacturing practices for decades. IPA’s experienced & innovative team used a simple engineering design and modern approach with functional improvements as the top priority. It features a single GMP tubular base design that meets the requirements for industrial, pharmaceutical, and nutraceutical applications. The base is powder coated to withstand most harsh cleaning agents and allows for drainage to avoid standing water. IPA’s flywheels are designed for ease of removal and installation, minimizing down-time and improving efficiency when maintaining equipment in the field.

This stainless steel mill series includes seven models, all of which can be configured to produce particle size distributions from half inch to 80 mesh. Historically, this mill has been preferred to process dried foods & purees, reclaimed off spec materials, all nutraceutical based products, and various chemicals.

IPA Models: LSM, PM6x15, M6x15, M12x15, M8x22, M12x22, M20x22, M30x28

Equivalents: L1A, D6A, DASO6, DKASO12, FASO8, FASO12, FASO20, HASO30

Rental Units Available Upon Request – Contact Us today

1. Feed Throat

2. Bearings

3. Chamber

4. Frequency Drive

Dairy Mills

Dairy Mills

IPA manufactures a mill design built according the USDA Dairy guidelines. It is the classic workhorse for processing hard cheeses, lactose, and whey. This unit is preferred in the Dairy and Food industries as it is designed and machined using plate weldments. Due to the generally harsh washing demands of dairy mills, it’s manufactured using high polish, unexposed threads, and continuous radius welds to ease the task.