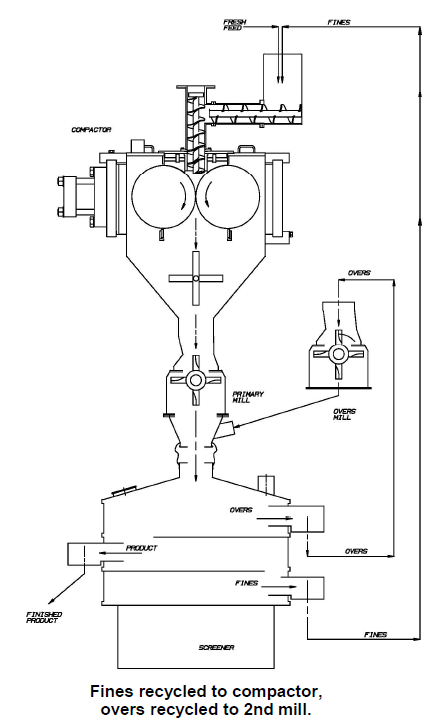

A typical roll compaction system is configured with an initial feeding device, roll compactor, mill, screener, and conveyor. Material enters the compactor (via twin feed screw design), is formed into compact, milled, and screened to separate recycle from the final product. The fines & overs are blended with fresh feed and recycled back into the compactor. At times, a secondary mill for regrinding overs, also known as a regrind loop, is beneficial to increase the system’s overall production rate.

A typical roll compaction system is configured with an initial feeding device, roll compactor, mill, screener, and conveyor. Material enters the compactor (via twin feed screw design), is formed into compact, milled, and screened to separate recycle from the final product. The fines & overs are blended with fresh feed and recycled back into the compactor. At times, a secondary mill for regrinding overs, also known as a regrind loop, is beneficial to increase the system’s overall production rate.

In an ideal situation, a roll compaction system produces a first pass yield of 50% or greater. When a single mill compactor system produces 35% yield or less, a secondary milling circuit is strongly recommended in order to increase the yield to a minimum of 45-50%.

Secondary milling is common in systems with high production rates or when the objective particle size distribution (PSD) is narrow. The expectation of an additional mill should be to increase the total product yield between 8 – 20% depending on the system, the integrity of the feed material, and PSD required. Addition of a secondary mill is economically efficient when it accomplishes two main objectives:

(1) Applies a larger force to the particle than the primary mill

(2) Creates a particle size that compliments the objective PSD

The Philosophy

In a roll compaction system, ‘overs’ are considered any particles larger than the top screen size of a screener. Overs are known to create excess heat and lower the total system yield when recycled through a compactor. When a system experiences these conditions, a secondary milling circuit is a cost effective solution with quick return on investment.

– Particle Properties –

Overs that have ‘survived’ the primary mill settings are now harder, smaller, more uniform, and require a greater energy to fracture the granule. Using the same blade type, rotor speed, and screen in the secondary mill will be of little to no benefit as the overs have already been exposed to this force and did not reduce to the objective PSD during primary milling. To optimize the performance of the system, a secondary mill should be configured with a different blade type, speed, and screen. Using the same mill settings in the regrind loop would allow the overs to accumulate within the circuit, causing the secondary mill to operate at a high amperage and overload the top screener deck. To produce the highest product yield from the secondary mill, a greater force must be placed on the particle in order to fracture it down to the desired particle size. IPA typically supplies secondary milling circuits with the following: (a) impact blades, (b) a minimum of one screen size smaller than the primary mill, and (c) a rotor speed on average 30% higher than the primary mill speed. By changing the settings of the secondary mill, the overs can be efficiently milled into acceptable product.

Narrow PSD Systems

A narrow PSD will range from product to product but is ultimately determined by the yield achieved. In this type of system, the primary mill parameters should be adjusted to produce 20-25% overs. Overs are then processed through a secondary mill and, with proper mill configuration, will achieve a minimum of 50% product yield.

For example, when the primary mill achieves a 35% product yield, the 24% overs produced are sent to a secondary milling circuit to achieve a 50% yield. This results in a 12% production increase and a total system yield of 47%.

Important to Note:

The addition of a secondary mill to an existing system will increase the volume of material going to the screener. Screener sizing should be evaluated & reviewed with your manufacturer.

High Capacity Systems

Many manufacturing plants with high capacity systems do not consider the addition of an overs regrind loop to be beneficial. While this can occasionally be true, increasing product yield by even 5% can have a significant economical and financial benefit.

For example, consider a system producing 5,000lbs/hour of final product and 10% overs. A secondary mill will create 500lbs/hour of product at 50% yield. This will produce an additional 500lbs/hour, 24 hours per day. In one day this regrind loop would yield an additional 12,000lbs of product.

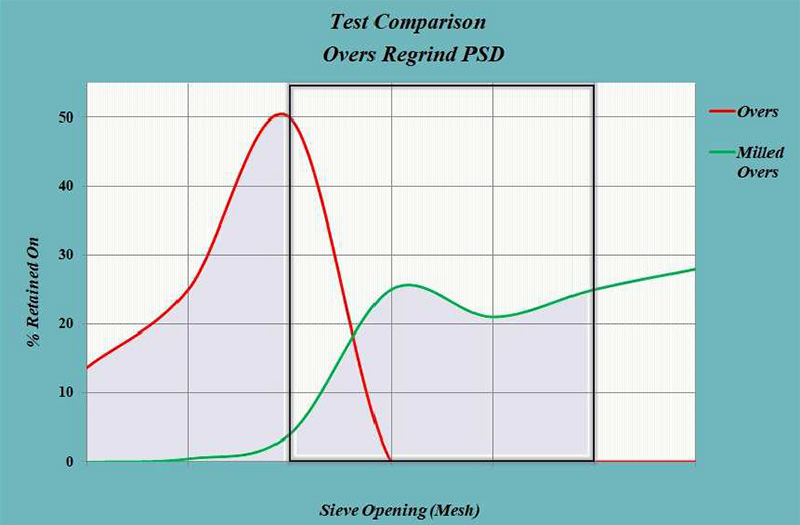

To maximize the use of a secondary mill, it is necessary to understand material properties, how the physical characteristics of overs change after the first pass, and how to adjust the milling parameters accordingly. In the graph below, the distribution of overs produced from the primary mill is represented on the left sided red curve. The shaded area equates to percentage of overs and the unshaded area, inside the box, is the amount of acceptable product retained in the overs. A small percentage of good product combined with the overs is typical with all screener manufacturers in this type of application. The green curve represents overs milled to a distribution achieving a maximum of 5-8%. This percentage is critical to achieve in order to prevent the overs from accumulating in the regrind loop. The shaded area within the green curve demonstrates the amount of good product produced from the secondary mill.

Review of the Graph Below