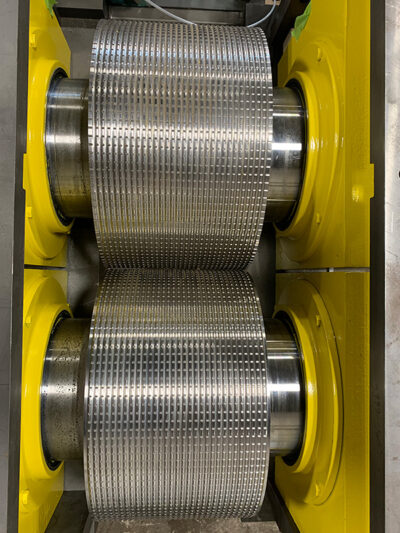

Roller compaction is commonly used for dry granulation in the industrial, pharmaceutical, & nutraceutical industries. It involves a combination of compression and milling to create granules of uniform size and shape. Roller compaction is a highly efficient, cost-effective process; making it an ideal choice for many applications.

Roller compaction is commonly used for dry granulation in the industrial, pharmaceutical, & nutraceutical industries. It involves a combination of compression and milling to create granules of uniform size and shape. Roller compaction is a highly efficient, cost-effective process; making it an ideal choice for many applications.

Dry granulation equipment specifically a roll compactor, is particularly useful for applications that require stable and durable granules. The process produces granules with a higher density, making them less likely to break or crumble during handling and transportation. This is important for applications where product stability is crucial, such as in the pharmaceutical industry.

Roller compactors for dry granulation are highly efficient at producing granules quickly and with minimal waste. This is because the process does not require the use of liquids or solvents, reducing the time required for cleaning and validation processes. Additionally, roller compactors can be easily customized to meet the specific needs of the manufacturer, producing granules that are tailored to the application.

One of the main advantages of dry granulation is it’s highly adaptable to different types of powders. Roller compaction can be used to create granules from a wide range of powders, including those that are heat-sensitive or have poor solubility. This is particularly useful in the pharmaceutical industry, where different types of active pharmaceutical ingredients (APIs) require different processing methods.

All things considered, roller compaction equipment for dry granulation is a highly efficient and cost-effective process that can be used for a wide range of applications. Its benefits include stable and durable granules, high efficiency, minimal waste, and adaptability to different types of powders. IPA can assist in determining the correct roller compaction system specific for your requirements, so you as the manufacturer can ensure high quality and consistent particle size distribution across all applications.