Common Misconceptions

- An Impact mill creates more fines than the Comil.

TRUTH: Impacting the particle reduced overall fines, as compared to the Comil “crushing” method. - An Impact mill creates a wider particle size distribution compared to a Comil.

TRUTH: An impact mill hits each particle with the same impact force, creating a uniform distribution. The ‘V’ shaped rotor in a comil has different tip speeds along the blade, creating a different impact force on each particle and a wider distribution. - Impact mills are more difficult to clean than a Comil

TRUTH: When comparing the base model IPA M6 Mill to a base model Comil, the disassembly and cleaning process is proven to be equivalent in time and manual labor.

Impact Mill

“In-Air” Size Reduction

Material enters the milling chamber, is impacted by the rotating blades “in air,” and exits through the screen. The objective of impact milling is to shatter material along its natural ‘fracture point’ resulting in the highest first impact yield. This minimizes the percentage of material requiring a second impact, maintains a lower temperature, and reduces overall fines generation.

Comil

“Crushing” Size Reduction

Material enters into the center of the chamber where centrifugal forces move the product towards the screen. As material travels through the rotor and to the screen, it is impacted once on the back side of the rotor and a second time between the rotor and screen, prior to exiting. Particles requiring further size reduction travel upward against the screen and are then reduced via “crushing.” This milling philosophy typically operates at a higher temperature and increases the percentage of fines due to length of time inside the chamber.

Another Way To Look At It

The following Ice Cube Analogy is another way to describe & compare both milling concepts. Imagine the particle is an ice cube. An Impact Mill is equivalent to throwing an ice cube in the air with one hand, and striking it mid-air with a knife in the other hand. The ice cube will shatter into a number of similarly shaped, coarser pieces.— A Comil is equivalent to placing an ice cube on a table and using the back side of a spoon to push down until it breaks (simulating a rounded rotor bar pushing material against the screen). This ‘crushing’ technique, compared to the Impact Mill, creates many pieces of various sizes, large and small, with an overall broader particle distribution. This concept is further driven to conclusion with the data and charts below.

Side-by-Side Data Analysis

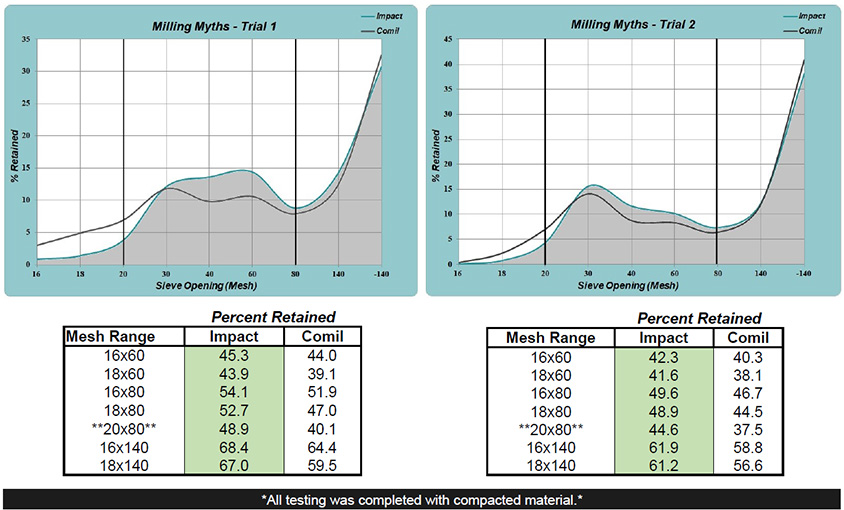

IPA supported independent testing of roll compacted products using both the IPA Impact Mill and a Comil. The results below address industry misconceptions and conclude the Impact Milling method is more efficient than the Comil method. A total of 4 products were tested with consistent results; Below is the analysis of 2 out of 4 products.

The Results – IPA Mill is Best Choice Under a Compactor

The IPA M6 Mill was set up with 425SH blades and the Comil with a 1615 Rotor for various products tested. In all tests, the IPA Mill produced less fines and a narrower distribution as compared to the Comil. The bolded lines within each graph highlight a 20×80 product cut with a markedly greater percent retained by the IPA mill, 8.8% and 7.1%, respectively. The green highlighted portions of each chart reflect additional product cuts in which the Impact Mill continued to outperform the Comil with higher product yields. Additionally, it should be noted the Impact Mill produced less overs and less fines. Previous lab tests comparing the Impact and Comil have also indicated the Impact Mill is most efficient, however those tests were not documented under a controlled design of experiments (DOE), as this comparison was conducted.