Engineered Milling Systems for Consistent Particle Size Control

At Innovative Process Applications (IPA), we specialize in advanced size reduction technology for the industrial, pharmaceutical, and nutraceutical industries. IPA designs and manufactures brand new milling systems specifically tailored to match or exceed Fitzmill® performance. We offer the same reliability, flexibility, and performance you expect — at a more competitive price point and with modern design improvements.

If you're searching for a Fitzmill replacement, Fitzmill equivalent, or Fitzpatrick-style comminuting mill, the IPA Mill delivers proven results with faster lead times, lower maintenance costs, existing customer support, and full parts interchangeability.

Why IPA's Mills are a Smart Alternative

When you choose an IPA mill equivalent to a FitzMill, you benefit from:

- Fresh equipment, full build to spec: IPA builds brand-new mill systems with modern components, so you're not inheriting undocumented history or out-dated controls.

- Design fidelity and compatibility with FitzMill applications: We know many users are accustomed to FitzMill style performance and results. Our equipment mirrors or exceeds those benchmarks — optimized for particle size reduction, de-lumping, comminution, and throughput ranges commonly associated with FitzMill machines.

- Better maintainability, parts availability and lifecycle support: A used machine may have hard-to-find spares, outdated controls, and ambiguous service history. With IPA you receive modern componentry, documentation, and support channels.

- Flexibility and customization: Since the equipment is OEM by IPA, you can specify features for your material, feed style, containment requirements, automation level, and future-proofing (e.g., cleanability, sanitary design, regulatory compliance).

- Reduced risk of downtime and hidden cost: A used machine may require unseen refurbishing, uncertain performance, or shortened remaining life. A new IPA machine gives you full life ahead — reducing the risk of early failure or unexpected rebuilds.

- Expertise: The experienced partners of IPA share over 60 years of Fitzpatrick history together, understanding the evolution of the Fitzmill design.

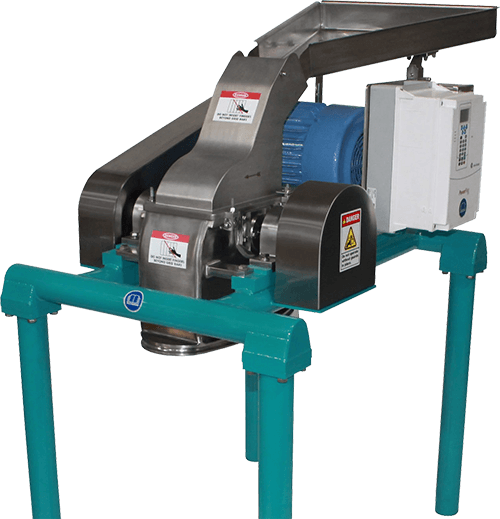

- Features: The IPA Mill features a single GMP tubular base design, powder coated base to withstand harsh cleaning components, flywheels designed for ease of removal and installation, all stainless steel product contact parts.

Applications

Our mills are ideal for:

- Processed dried foods & purees

- Herbal Supplements

- Hard Cheese

- Textured Soy Protein

- Reclaim and rework processes

A Proven Fitzmill® Alternative with Service You Can Trust

Customers who switch from a Fitzmill to the IPA Mill report equivalent or better particle size control, quieter operation, and easier maintenance. The IPA Mill is a direct mechanical equivalent to the Fitzpatrick Fitzmill, offering full compatibility with screens, blades, and rotor assemblies. IPA also provides replacement parts, screens, and service support for most Fitzmill models, helping you extend the life of your existing Fitzpatrick equipment or transition smoothly to an IPA Mill.

1. Feed Throat

2. Bearings

3. Chamber

4. Frequency Drive

Dairy Mills

Dairy Mills

IPA manufactures a mill design built according the USDA Dairy guidelines. It is the classic workhorse for processing hard cheeses, lactose, and whey. This unit is preferred in the Dairy and Food industries as it is designed and machined using plate weldments. Due to the generally harsh washing demands of dairy mills, it’s manufactured using high polish, unexposed threads, and continuous radius welds to ease the task.