IPA partners have extensive experience & knowledge in designing and manufacturing size reduction equipment, roller compaction systems with twin feed screw design, and PLC controls. Our team worked exclusively with Fitzpatrick’s FitzmillTM & ChilsonatorTM line for years, giving us an intimate understanding of the equipment.

IPA transforms outdated equipment into quality re-builds for optimal performance with future applications. Our goal is to update your equipment to the latest OSHA safety standards and refurbish only what is required, nothing more.

Our process to bring your equipment back to life typically involves:

- Tear-Down & Inspection

- Provide a Full, Detailed Quote (replacing parts only as necessary)

- Polish Stainless Steel or Powder Coat Mild Steel

- Replace All Bearings

- Inspection + Test Run

Contact us today for assistance with your equipment.

Mills/Granulator

- Specializing in Fitzmill™/Fitzpatrick Equipment

- Complete machine rebuild to current safety standards

- Rotor rebuilds (blades, bearings, seals, & packing)

- Supported machines listed below

- L1A

- M5A

- D6A

- DASO6

- DKASO6

- DKASO12

- FASO8

- FASO12

- FASO20

- HASO30

*All variations of the above models

PLC/Controls Upgrade

- Replace discontinued relay logic

- Replace worn out touchscreens (including CTC models)

- Update obsolete units with a complete new control system

- Support Fitzmills™ & Chilsonators™

Compactors

- Specializing in Fitzpatrick Chilsonator™

- Complete machine rebuild to current safety standards

- Roll rebuilds

- Supported machines listed below

- L83

- L89

- IR220

- IR520

- IR4X10

- 4X10

- 7X10

- 12X12

- 12X16

- 12X20

- 16X20

Reconditioned Inventory Sale

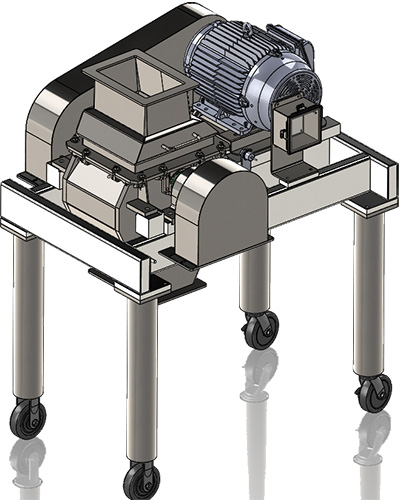

Model VFS-DASO6

- Fully Refurbished – new controls, motor, feed hopper

- Updated to the latest safety standards

- Blades & screen configurable for your application

- Stainless steel product contact parts

- Delivery in 6 weeks