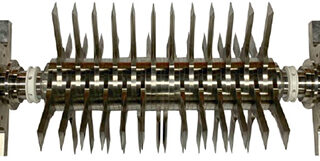

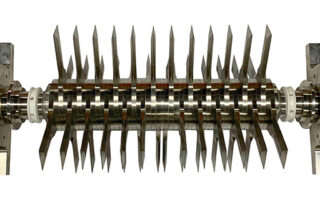

Powder Processing Mills – Rotor Repairs & Rebuilds

PRINT THIS POST IPA designs and manufactures powder processing equipment known for strong performance & durability. Specifically, the IPA Mill requires minimal maintenance & is built for the most rugged applications. Although routine inspections are always advised, mills will occasionally require replacement parts to sustain optimal performance

What does the IPA Mill do? Features & Benefits

The IPA Mill, similar to the Fitzpatrick Fitzmill, is a type of comminutor used in various industries, including pharmaceuticals, food processing, and chemical manufacturing. The primary function of the IPA Mill & Fitzmill is to reduce the size of particles through a size reduction process, making it a crucial tool

The Benefits of Roller Compaction Over Slugging

Slugging and roller compaction are both used in the industrial, pharmaceutical, & nutraceutical industry for granulation, but they differ in their processes and outcomes. While both slugging and roller compaction are methods of granulation in manufacturing, roller compaction is often favored for its efficiency, control over particle size, and suitability

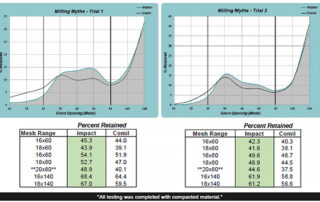

Impact Milling Vs. Comil

PRINT THIS POST Common Misconceptions An Impact mill creates more fines than the Comil. TRUTH: Impacting the particle reduced overall fines, as compared to the Comil “crushing” method. An Impact mill creates a wider particle size distribution compared to a Comil. TRUTH: An impact mill hits each particle with the

IPA’s Quality Aftermarket Support & Spare Parts

PRINT THIS POST When it comes to roller compactors and size reduction equipment, ensuring optimal performance and efficiency is crucial for businesses. However, as time goes by, even the most robust machinery may require replacement parts to maintain its functionality. That's where IPA's Aftermarket Support and Spare Parts come

A Smooth Transition: Contract Manufacturing to IPA Roller Compaction Sales

PRINT THIS POST Roller compaction equipment plays a vital role in transforming powdered materials into compacted sheets, offering enhanced efficiency and productivity when processing for further use. The IPA Roller Compactor is designed and manufactured in-house with equivalents to the Fitzpatrick Chilsonator. IPA can provide full- scale services with initial

Roller Compactors for Dry Granulation

PRINT THIS POST Roller compaction is commonly used for dry granulation in the industrial, pharmaceutical, & nutraceutical industries. It involves a combination of compression and milling to create granules of uniform size and shape. Roller compaction is a highly efficient, cost-effective process; making it an ideal choice for many

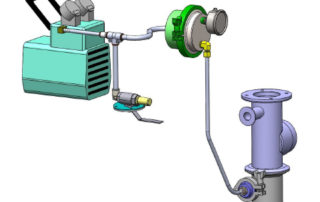

The ABCs of Vacuum Deaeration

PRINT THIS POST A main function of roll compaction includes the removal of air between material particles to form a hard sheet of compact. When compacting with a twin feed screw design, the majority of materials can be processed efficiently. However, there are still some materials that cannot achieve

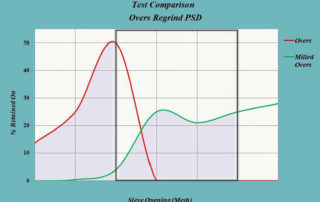

When to Consider Overs Regrind Loop

PRINT THIS POST A typical roll compaction system is configured with an initial feeding device, roll compactor, mill, screener, and conveyor. Material enters the compactor (via twin feed screw design), is formed into compact, milled, and screened to separate recycle from the final product. The fines & overs are blended

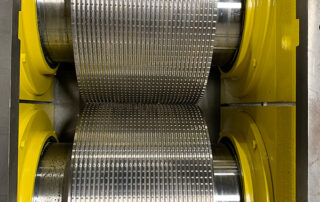

Compactor Roll Refurbishment

Print this Post The heart of any roll compaction process is the roll surface. It is common for system efficiency to unknowingly diminish overtime for a number of reasons - employee turn over (both operators & maintenance), changes to the equipment itself, and changes made to

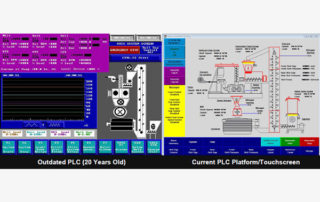

Updating PLC Controls—Fitting it into Your Long Term Plan

Print this Post How Old are the PLC Controls on your Roll Compactor/Mill? While you may have recently upgraded your HMI (touchscreen), it is important to understand that the PLC controls are the heart of your operation. This update is often overlooked due to high cost,

Spare Parts, Maintenance & When to Consider

Print this Post IPA roll compactors and mills are durable machines built for long lasting run time. However, all machines require maintenance and often replacing of parts to continue producing optimum product quality and throughputs. Production rates can unknowingly decline over time from a process issue or deteriorating parts.Whether

Contract Manufacturing – When is this beneficial

Print this Post Customers frequently ask the questions “when & how long is contract manufacturing best for my product? Is it cost effective?" There are many individual situations amongst companies with often individual answers, as each has a different/unique concern with their application. Here is a general guideline of